AsianScientist (May 9, 2013) –Scientists in China have developed a method to print flexible electronic circuits on paper using liquid metal ink, which paves the way for a simple, low-cost method for printing paper electronics.

To produce conventional printed circuit boards or electronic devices, metal is generally deposited on a surface by complex methods, which consume much time and energy. Paper is an attractive material for making flexible electronics because it is cheap and easy to work with. However, unlike normal print ink, electrical inks are difficult to print onto paper because of their extremely large surface tension.

A team of scientists led by Prof. Jing Liu from the Chinese Academy of Sciences in Beijing, China, has overcome some of the issues that have impeded reliable printing of circuits. Publishing in the journal Scientific Reports, they describe the concept of Printed-Circuits-on-Paper (PCP), essentially a printing principle for 3D functional electronics devices.

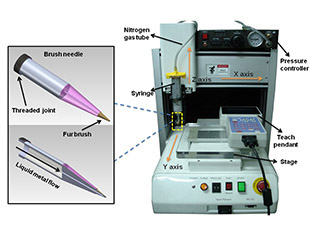

Firstly, the scientists improved the adhesion of liquid metal alloy ink by an oxidation strategy. To overcome the high surface tension of the ink, the team designed new printing machinery with a brush-like porous pinhead. Lastly, they identified specially coated paper that offered the best surface to which the ink could attach. Importantly, the whole printing process can be performed at room temperature, “just like printing pictures on paper on an office printer,” says Prof. Liu.

Desktop printer and printing pinhead for liquid metal ink, packaging material and paper electronics. Photo: Prof. Jing Liu.

Using their new technique, the researchers have successfully printed typical circuits and functional components such as conductive wires, inductance coils and flexible antennae. By incorporating vulcanized silicone rubber as isolating inks, the team has also developed a way to directly print a three-dimensional (3D) hybrid electro-mechanical device, an advance over currently available 3D printers that can only print mechanical objects without electronics inside.

Prof. Liu hopes his team’s new technique could be used in applications as varied as rapid-prototyping circuits, integrated circuits on paper, sensors, 3D mechanical switches and antennae, electric solar cell arrays and functional radio-frequency identification (RFID) tags on books.

Looking to the future, Prof. Liu says, “So far, the prototyping machine is still somewhat expensive. We are striving to make it affordable for daily routine use, say, offering an ordinary office electronics printer. In addition, better circuital uniformity and resolution can still be possible.”

The article can be found at: Zheng Y et al. (2013) Direct Desktop Printed-Circuits-on-Paper Flexible Electronics.