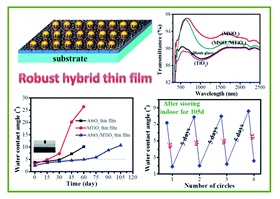

Scientists from the Technical Institute of Physics and Chemistry of the Chinese Academy of Sciences (TIPCCAS) reported a facile dip-coating approach to fabricate mechanically robust hybrid thin films with high transmittance and durable superhydrophilicity. Glass substrates were first coated with a mesostructured SiO2 thin film (MSiO2) by acid catalysis. The thin film is continuously mesoporous with antireflective and self-cleaning properties. Then, the substrate with MSiO2 thin film was covered with a mesoporous TiO2 thin film (MTiO2) by dip-coating. The maximum transmittance of the hybrid thin film coated substrate is as high as 96.9% at 620 nm. The film surface showed an outstanding superhydrophilic property (water contact angle less than 1° in 0.5 s). The superhydrophilicity of the as-prepared double layer thin film could last for 60 days, which is much better than those of the as-prepared SiO2 thin film (30 days) and the as-prepared TiO2 thin film (15 days). The MSiO2–MTiO2 thin film lost its superhydrophilicity after being stored in the dark for 105 days, but its superhydrophilicity could be restored by UV illumination. It could maintain its self-cleaning property after repeated storage and UV irradiation cycles, suggesting self-healing superhydrophilicity by UV irradiation. Taber abrasion test, sand impact test and washing test showed that the hybrid thin film had excellent mechanical robustness and could remain nearly intact during these tests. SEM, AFM, BET and XRD were employed to characterize the morphology, porosity and crystal form of the hybrid thin film. Methylene blue photodegradation was examined to evaluate the photocatalytic activity of the hybrid thin film. The MSiO2–MTiO2 coated glasses have potential in various areas, like solar cells, windowpanes and eyeglasses, and may also find applications in membrane-based separation, selective catalysis and sensors.

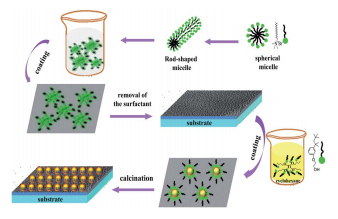

Schematic illustration of the formation mechanism of MSiO2–MTiO2 hybrid thin film.

|