Thermoacoustic technology is becoming increasingly attractive because of its high reliability and environmental friendliness. The double-acting traveling-wave thermoacoustic heat engine using liquid pistons, proposed by our group, can improve the thermoacoustic conversion efficiency further and yield a more compact engine. In this study, three different environmentally friendly working gases, helium, nitrogen and carbon dioxide, were studied experimentally, primarily in terms of thermoacoustic conversion parameters, including the onset temperature, the resonant frequency, and the pressure ratio, under different working mean pressures. Results show that the working gas significantly influences thermoacoustic performance. They also suggest a very encouraging application prospect for this novel thermoacoustic heat engine. Finally, we performed theoretical analysis to better understand thermoacoustic conversion with the different working gases. Energy, 2014

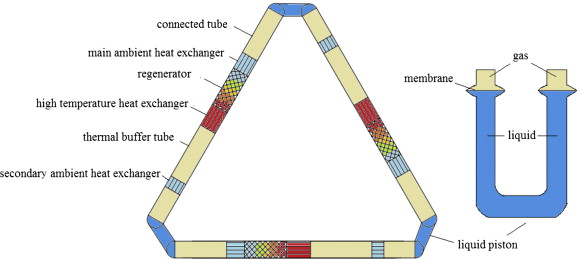

Schematic diagram of the liquid-piston travelling-wave thermoacoustic heat engine.

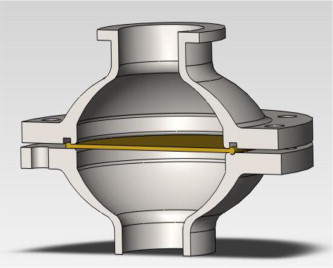

Membrane configuration.

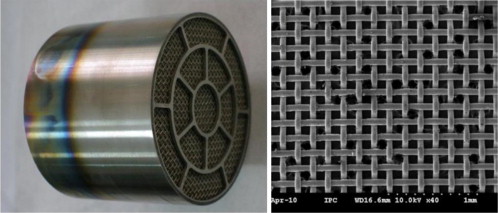

The regenerator and the stainless-steel mesh. |