Both bimodal and unimodal AlON powders were pressureless sintered and their phase assemblages and microstructure evolutions at 1400–1900 °C were monitored to reveal the fast densification mechanism of bimodal powder. Phase assemblages analysis of samples sintered at 1400 °C suggests that fine AlON particles were transformed into hexagonal α-Al2O3 and AlN, while coarse AlON particles were transformed into cubic η-Al2O3 and AlN. Correspondingly, only a small fraction of the unimodal mixture was η-Al2O3, while the relatively unstable η-Al2O3 kept dominating the bimodal samples and most of them were directly reformed into AlON at a lower temperature of 1600–1700 °C for their similarity in crystal structure. As a result, a bimodal grain size distribution was kept in the whole sintering process of the bimodal sample, which led to its fast densification. Using the bimodal AlON powder, highly transparent AlON ceramics were fully pressureless sintered at 1820 °C after holding for 2.5 h. Journal of the European Ceramic Society, 2015

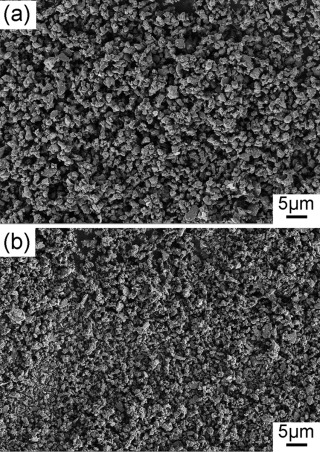

Fig. 1. SEM images of the bimodal (a) and unimodal (b) AlON powders. |