Internally triggered motion of an object owns important potential in diverse application areas ranging from micromachines, actuator or sensor, to self-assembly of superstructures. A new conceptual liquid metal machine style has been presented here: the transient state machine that can work as either a large size robot, partial running elements, or just divide spontaneously running swarm of tiny motors. According to need, the discrete droplet machines as quickly generated through injecting the stream of a large liquid metal machine can combine back again to the original one. Over the process, each tiny machine just keeps its running, colliding, bouncing, or adhesion states until finally assembling into a single machine. Unlike the commonly encountered rigid machines, such transient state system can be reversible in working shapes. Depending on their surface tension, the autonomously traveling droplet motors can experience bouncing and colliding before undergoing total coalescence, arrested coalescence, or total bounce. This finding would help mold unconventional robot in the sense of transient state machine that could automatically transform among different geometries such as a single or swarm, small or large size, assembling and interaction, etc. It refreshes people's basic understandings on machines, liquid metal materials, fluid mechanics, and micromotors. Small, 2015

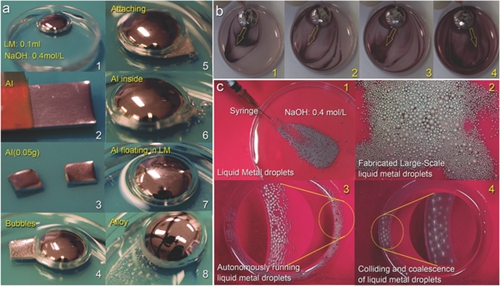

The alloy preparation and fabrication of autonomously running liquid metal machine. a) Liquid metal pool (0.1 mL) was deposited in a Petri dish and a piece of aluminum (0.05 g) was picked up by tweezers to attach to the liquid metal object (a1–a4). A lot of bubbles were generated when aluminum got in touch with the liquid metal in NaOH solution. After ≈30 min, aluminum was dissolved in liquid metal and the alloy was prepared, with high speed self-rotation (a5–a8). b) Ink was introduced to highlight the self-rotation of the alloy; ink was dropped from the top of the alloy droplet and then passed through the metal droplet to the front. c) The syringe was used to inject the alloy into the NaOH solution and to produce a large number of small liquid metal droplets (c1–c2). There were a lot of autonomously running droplet motors in the circular channel, and some of which collided and coalesced in the channel (c3–c4). |