Morphology greatly impacts the performance improvement of conducting polymers for signal detection, actuator microfabrication and droplet manipulation applications. However, most of the previous methods cannot satisfy practical demands due to their intrinsic drawbacks.

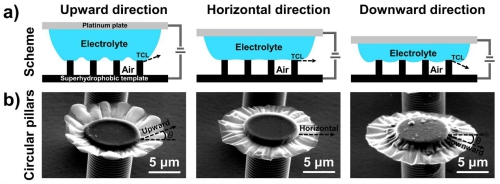

Here, Prof. Shutao Wang’ group developed a general strategy for the fabrication of patterned conducting polymers with precisely controlled microstructures (e.g., polypyrrole microsuckers) by regulating the solid/liquid/gas triphase interface and electrochemical polymerization. By regulating the distance between the Pt plate and micropillar-structured templates, the growth directions of the microsuckers on the pillar tops change from upward (+26 ± 5°) to downward (-32 ± 7°), and their positions to the pillar tops are changed from proximal to distal due to an adjustment in the solid/liquid/gas triphase interface. The influencing factors on the microsucker growth performance, such as the time and current of electrochemical polymerization, the shape and size of micropillars, the type of conducting polymers, were systematically investigated. Furthermore, the as-prepared microsuckers can be used for transporting water droplets because of their adjustable adhesion to water, which linearly increased from 33.5 ± 2.3 μN to 61.1 ± 1.2 μN with an increase in the projected epitaxial length of the microsuckers from 3.38 ± 0.39 μm to 8.78 ± 0.79 μm.

This research was published in Advanced Functional Materials (DOI:10.1002/adfm.201800240) entitled “Controlled Growth of Patterned Conducting Polymer Microsuckers on Superhydrophobic Micropillar-Structured Templates”.

Figure 1. Patterned polypyrrole (PPy) microsuckers with controllable growth directions deposited on superhydrophobic micropillar-structured silicon templates by the combination of solid/liquid/gas triphase interface regulation and electrochemical polymerization.

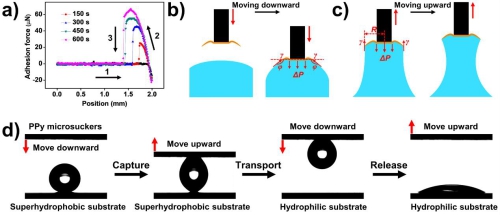

Figure 2. PPy microsuckers can be used as an artificial sucker hand to transport water droplets. a) The force–distance curves before and after the water droplet was in contact with the PPy microsuckers after different polymerization times, including 150, 300, 450, and 600 s. A single PPy microsucker was moved downward to capture the water droplet b) and moved upward to release the water droplet to the hydrophilic substrate c) by forming a capillary bridge. The adhesion force of a single PPy microsucker (F) results from the formation of a capillary bridge between the water droplet and the microsucker. d) The detailed process of water droplet transportation by using PPy microsuckers.

The corresponding authors are Prof. Shutao Wang and Prof. Jingxin Meng.

This research was supported by the National Research Fund for the National Natural Science Foundation (21425314, 21501184, 21434009 and 21421061), and the Top-Notch Young Talents Program of China, the Youth Innovation Promotion Association, CAS (2017036).

Article links: https://onlinelibrary.wiley.com/doi/10.1002/adfm.201800240