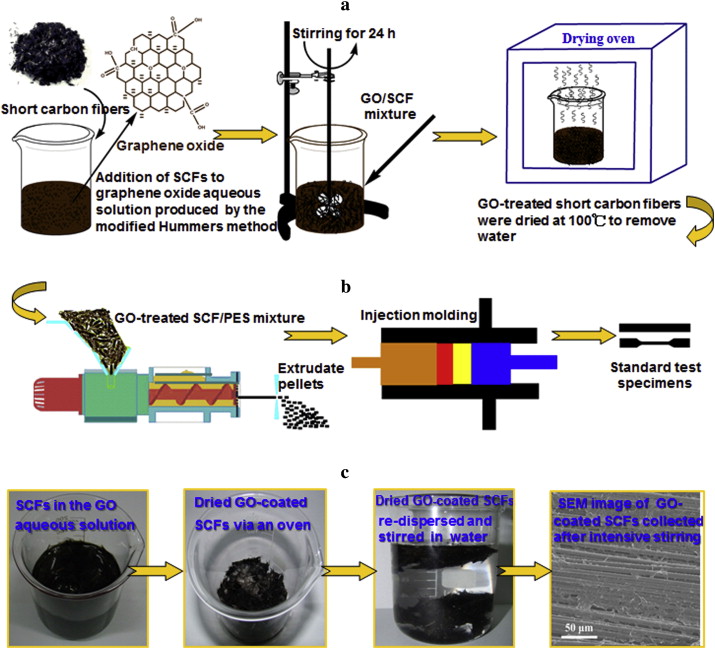

(a) Schematic of GO sizing onto short carbon fibers, (b) process chart of preparing composite specimens and (c) evaluation of the coating efficiency of GO onto the surfaces of SCFs. Polyethersulphone (PES) is an important special engineering plastic. In order to broaden its applications in automobile and sports fields etc., its mechanical properties have to be enhanced. This paper reports the effectively enhanced tensile and flexural properties of injection molded graphene oxide (GO)-coated short carbon fiber reinforced PES composites by GO coating. The GO content varies in a range of 0.0–1.0 wt%. First, the GO is employed as surface sizing agent to treat short carbon fibers (SCFs) by a facile physical absorption method. The GO-coated SCF/PES composites are extruded into pellets and then injection molded into tensile and flexural samples. It is shown that the GO coating on SCF surface leads to an obviously enhanced SCF/PES interfacial adhesion. As a result, both the tensile and flexural strengths are effectively enhanced by the GO coating on the SCF surfaces. The tensile and flexural moduli are also increased by the GO coating due to the excellent elastic modulus of GO. The optimal GO content is found to be 0.5 wt% for effectively improving the overall composite mechanical performance. Polymer, 2015 |