A team of researchers affiliated with several institutions in China has developed an emulsion interfacial polymerization method to fabricate Janus particles with chemical and topological anisotropy. Their paper published in journal Science Advances.

Polymer particle materials have a giant effect on human’s daily life, such as cosmetics, paint/coating, photosensitive materials, drug capsules and so on. Achieving these applications are largely governed by the topologies and surface chemistries of polymer particles. Emulsion polymerization is a traditionally leading synthesis technique of particle. However, it usually produces spherical particles due to surface tension, posing the challenge in tuning the topology and chemistry of the particles.

To overcome the limitation of surface tension, recently, Prof. Wang and co-workers have developed a general emulsion interfacial polymerization approach to synthesize a large variety of Janus particles with controllable topological and chemical anisotropy. In the study, they chose to use a typical oil-in-water emulsion system, the styrene (St) and divinyl benzene (DVB) in water emulsion, into which hydrophilic monomer (such as, acrylic acid (AA) or acrylamide (AM) et al. ) was introduced as anchoring molecules. The polymerization was initially designed to occur inside the oil droplets. They found that a particle nucleus could be produced inside of oil droplets and the particle nucleus would move toward the oil/water interface. In this case, the hydrophilic anchoring monomers in the external water phase could contact the particle nucleus and be initiated to polymerize, triggering interfacial anchoring polymerization.

On the interface, based on the equal chemical potential principle at equilibrium, preferential copolymerization of AA, St and DVB occurred along the interface in two directions, resulting in the formation of crescent-moon shaped Janus particles. Meanwhile, their theoretical simulation consistently suggested the preferential growth, similar to they obtained in the experiment. The novel method will significantly expand the utility of Janus particles, creating new opportunities in a wide variety of applications, ranging from environment to health, especially in oil-water separation and biological detection.

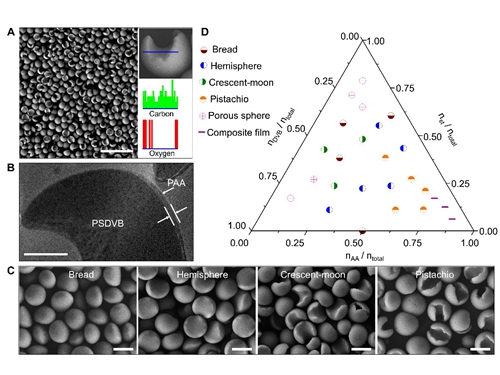

Fig. 1. Emulsion interfacial polymerization mechanism for producing Janus particles. (Image by Dr. FAN Junbing)

This approach can produce Janus with a crescent-moon topology and amphiphilicity (Fig.2). Their emulsion polymerization approach could produce uniform Janus particles of approximately 5 g in one batch, providing an effective way to synthesize Janus particles on a large-scale. The emulsion interfacial polymerization system has several distinct advantages over traditional emulsion polymerization. (i) The emulsion interfacial polymerization breaks the limitations of traditional emulsion polymerization. Starting from one anchoring point of the interface, the polymerization can break the uniform growth of particles at the entire interface of droplets, resulting in the formation of anisotropic Janus particles. (ii) The emulsion interfacial polymerization successfully overcomes the current challenges for achieving the tunability of the chemical and topological anisotropy of polymer particles. (iii) The emulsion interfacial polymerization is general.

The emulsion interfacial polymerization strategy can be used for polymerizing various vinyl monomers, including positively charged, neutrally charged and negatively charged ones, greatly enriching the community of Janus particles. This method can also be expanded to large-area fabricate two-dimensional Janus film actuator (Wang, et al. NPG Asia Mater. 2017, 9, e380). This approach will open a newly field of functional Janus materials and will greatly excite the development of conceptually novel interfacial polymerization-based chemistry and fabrication.

Fig. 2. Synthesis and characterization of the Janus particles. (Image by Prof. FAN Junbing)

This work was financially supported by National Natural Science Foundation, the Key Research Program of the Chinese Academy of Sciences, MOST, Beijing Municipal Science & Technology Commission. The author thanks the Prof. Zhongyuan Lu and Prof. Hong Liu in the Jilin university for the computer simulation and Prof. Lin Gu in the Institute of Physics, Chinese Academy of Sciences for the STEM images.

More information: J.B. Fan, Y. Song, S. Wang*, et al. A general strategy to synthesize chemically and topologically anisotropic Janus particles. Sci. Adv. 3, e1603203 (2017).

NEWS