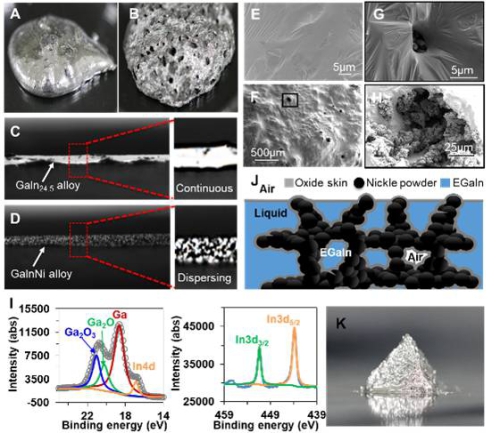

Recently, a joint research team from the Technical Institute of Physics and Chemistry (TIPC) of the Chinese Academy of Sciences and Tsinghua University reported for the first time a fundamental phenomenon of liquid metal welding nanoparticles. In the article of “Tang et al., Thin, Porous, and Conductive Networks of Metal Nanoparticles through Electrochemical Welding on a Liquid Metal Template, Advanced Materials Interfaces, Advanced Materials Interfaces, 2018: 1800406” (Cover story), the authors discovered that when the liquid metal pellets coated with metal nanoparticles were placed in an alkaline solution, the originally dispersed nano metal particles would be automatically connected to compose a porous network structure via a self-organized manner. Besides, such mesh structure is rather easy to peel off from the liquid metal base (Fig. 1). The reason lies in that the interface of the liquid metal is reducible and the surface of the copper nanoparticle would form an oxide due to oxidation. Therefore, an electrochemical reaction would occur inside the material systems owing to their different electrochemical potential in the alkaline solution. As a result, the oxides on the surface of the nanoparticles are reduced, which in turn causes the newly formed metallic copper to firmly bond the surrounding copper particles together. This event proceeds just like a classic metal welding process. For this reason, the authors named the phenomenon as "liquid metal welding nanoparticle effect".

According to the experiments, the particulate network has good mechanical strength whereby it can be peeled off from the liquid metal surface and then transferred to other substrates. Through measuring the conductivity of this special type of porous material composed of metal nano particles, it is found to be different from ordinary conductive metal materials: there occurs a resistance reduction caused by an electric field in the system. However, the test resistance would be suddenly increased by several orders of magnitude when the voltage becomes too much high, indicating that excessive voltage can cause failure of the conduction of the particle mesh. An in-depth interpretation disclosed that the reason causing decrease of electrical resistance lies in that the electrostatic action under the applied electric field induces the partially separated particle nets to be connected again to enlarge the conductive path. And the reason for the sudden resistance increase comes from the enhanced electro-migration under high current, so that the particles were broken and conductivity became lost. The above findings have led to the establishment of a method for weaving a micron-thick porous conductive particle network using liquid metal template, whereby the new material thus fabricated offers good mechanical strength and unique electrical properties.

Further, in another article entitled “Self-Growing and Serpentine Locomotion of Liquid Metal Induced by Copper Ions” (Chen et al., ACS Applied Materials & Interfaces DOI: 10.1021/acsami.8b07649), the TIPC team discovered a new self-growing liquid metal serpentine dispersion effect which is also the first ever report. In former works, a series of fundamental phenomena have been successively discovered and explained regarding liquid metal such as self-driving machines, surface Marangoni flow, and periodic self-oscillation effects. However, these deformation behaviors are more often displayed as a whole because of the large surface tension of liquid metal. The present large-scale discrete deformation and serpentine locomotion are no longer limited to single convection, rolling or integral deformation and significantly updated the forms of liquid metal movement and deformation.

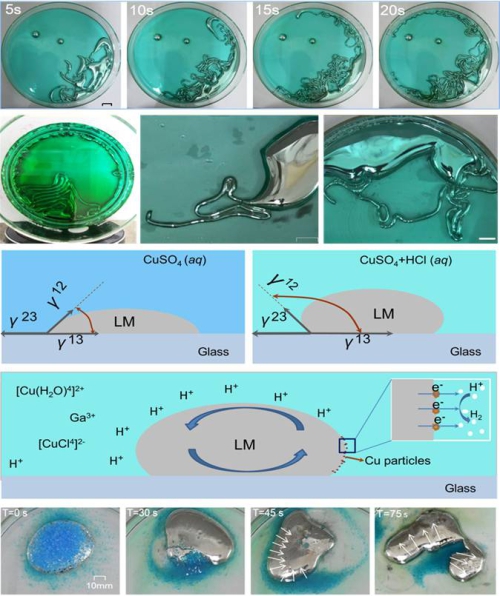

Studies disclosed that the bulk liquid metal immersed in acidic CuSO4 solution will generate tremendous discrete snake-like extensions (pseudopodia) spontaneously. These pseudopodia continued to grow just like slim snakes until the entire bulk liquid metal was consumed and changed into a lot of dendritic strips (Fig. 2). The mechanism lying behind this phenomenon is mainly that the numerous tiny Cu-Ga galvanic cells formed by the displacement reaction are generated at the interface of between liquid metal and copper salt solution, which changes the surface tension of the liquid metal, resulting in an unbalanced interface pressure eventually led to the occurrence of serpentine movement. Here, the acidity of the solution has a great influence based on the experimental results. Under suitable acidic conditions, the formation and velocity of the serpentine locomotion of liquid metal can be controlled by adjusting the acidity. Moreover, such serpentine motion can be excited multiple times, greatly increasing the durability of the movement. The study further reveals that the unique environment of the acidic copper salt solution ensures that numerous copper particles can be continuously and stably precipitated and phagocytized. Such dynamic equilibrium is a deep-seated cause of the phenomenon of serpentine dispersion movement. This phenomenon enriches the scientific picture of the liquid metal material world and further expands the theoretical and technical connotation of the liquid metal soft machine that has emerged in recent years.

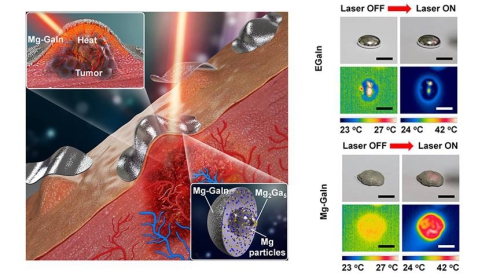

In addition to the above fundamental findings, the joint team also made a series of new advancements on a group of practical technologies for liquid metals, which spans from developing new biomedical materials for cancer treatment (Fig. 3; Wang et al., Advanced Healthcare Materials, 2018), high performance electronic ink (Fig. 4; Chang et al., Advanced Materials Interfaces, 2018), wearable medical device (cover article; Guo et al., Adv. Eng. Mater., 2018), stretchable skin electronics (Guo et al., Science China Technological Sciences, 2018) and flexible robot sensing and control system (Guo et al., Smart Materials and Structures, 2018). Facing the urgent needs from the above newly emerging fields, the team successfully proposed and demonstrated a series of important practical technologies.

The team’s researches were supported by NSFC Key Project under Grant No. 91748206, Dean’s Research Funding and the Frontier Project of the Chinese Academy of Sciences.

Figure 1. The journal cover story and its reflected porous mesh material generated by the liquid metal welding nanoparticle effect.

Figure 2. Self-growing liquid metal dispersion effect, serpentine motion phenomenon and partial mechanism analysis.

Figure 3. Mg based liquid metal skin coating material and its application in the treatment of tumors by near-infrared laser ablation.

Figure 4. High performance Ni-based liquid metal e-ink material with good printing characteristics.

Article Links and videos:

1. https://www.onlinelibrary.wiley.com/doi/abs/10.1002/admi.201800406

2. https://pubs.acs.org/doi/abs/10.1021/acsami.8b07649

3. https://www.onlinelibrary.wiley.com/doi/abs/10.1002/adhm.201800318

4. https://www.onlinelibrary.wiley.com/doi/abs/10.1002/admi.201800571

5. https://onlinelibrary.wiley.com/doi/abs/10.1002/adem.201800054

6.http://engine.scichina.com/publisher/scp/journal/SCTS/doi/10.1007/s11431-018-9253-9?slug=full%20text

7. http://iopscience.iop.org/article/10.1088/1361-665X/aacbf6

NEWS